Heat treatments carried out in the ECM Technologies Turquoise vacuum furnaces are specifically tailored to alloys prone to oxidation: Nickel, Titanium, Cobalt, Chrome, Molybdenum as well as Tungsten. All require to be treated under primary or secondary vacuum.

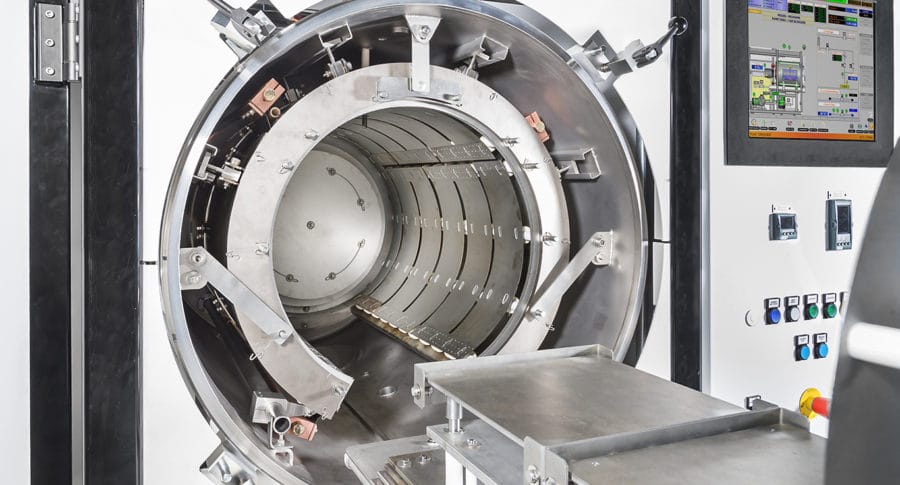

The design of the Turquoise furnace allows external loading, with a load directly conveyed by the door of the furnace. This system is specifically adapted to an integration within a clean environment. This compact installation allows a wide range of treatments with working temperatures up to 1600°C, while working under primary or secondary vacuum.