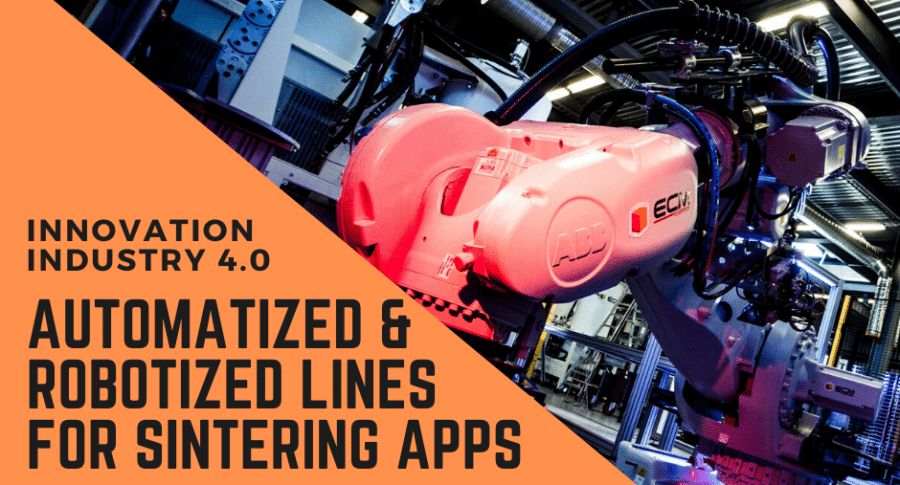

Robotized lines for vacuum sintering applications

ECM Technologies acquired skills and know how in the manufacturing of vacuum furnaces for high tech applications for more than 50 years, and developed its robotics skills for all kinds of applications. These include silicon wafers manipulation at high speed as well as heavy loads handling, in addition to tracking systems enabling the identification of potential defects on parts.

A unique contact: furnaces + robots

All of the aforementioned skills let ECM Technologies supply robotized installations, mastering furnaces technical aspects as well as their compatibility with automated systems. This allows ECM Technologies to deal with projects from start to finish with strong reactivity and efficiency from furnaces till their robotization. Hence, it intervenes as a unique interlocutor for its clients in projects getting more and more complex.

This was recently the case for the supply of a large scale production line of ceramic parts issued from high temperature vacuum sintering. These parts are manipulated at high speed to build up loads before sintering phases – close to 3000 parts per load – and for the loading / unloading of the furnace – one from the Cristal range.

A heat treatment expertise associated to robotics

Following this first significant order, ECM Technologies is about to commission a second line of the same kind for similar applications. This first reference gives even more credit to ECM Robotics, an ECM Technologies’ division, for fragile parts loading and unloading at high speed.

Furthermore, this allowed validating the effectiveness and performance of vacuum furnaces from the Cristal range, which hot zones are metallic for clean applications, at high temperature (1800°C) with high vacuum levels.

The in line integration of this know-how opens new markets and lets ECM Technologies move another step forward in the 4.0 era.