- High precision in the assembly and welding phases

- High process repeatability

- Unrivaled welding quality

- Total line management and optimized traceability

- Error reduction & increase in productivity

Robotized solutions for battery pack manufacturing

Robotized solutions for battery pack manufacturing

Avantages

A global offer

ECM Robotics has years of experience in various fields. From photovoltaic applications requiring high speed handling, to semiconductor applications requiring extreme precision, to the automotive industry, which requires high productivity with heavy parts handling, the ECM Group’s robotics skills can address all sectors.

Thus, ECM Robotics, together with its partners, accompanies you in the manufacturing of your batteries and in the automation of these processes guaranteeing you quality, repeatability and profitability. Indeed, the developed solutions cover the different steps of the value chain:

Control

Automatic measurement of the electrical voltage of each cell before the assembly phase

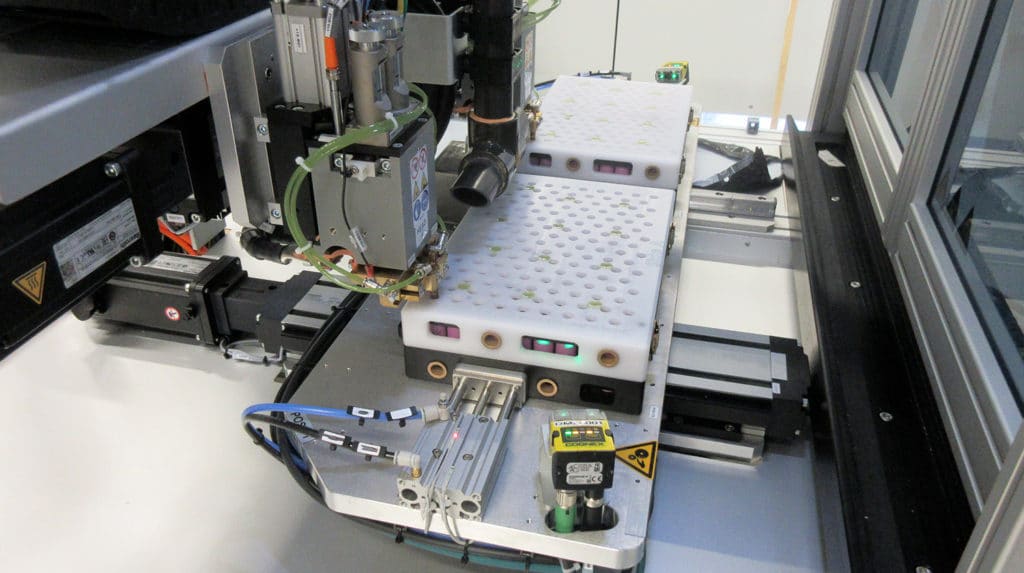

Assembly

Tested cells are automatically assembled into battery packs

Welding

The assembled cells are spot welded using resistance welding

Tracking

The welding information of each cell is collected and identified, then sent to a centralized supervision system