Heat Treatment expertise in a modular & multi-processes installation

ECM Technologies is a key player in the heat treatment industry, widely recognized around the world thanks to its expertise in vacuum technologies and its patented low pressure carburizing process. With a constant efforts in innovation and strong investments in R&D, ECM Technologies keeps developing even more efficient and cleaner production tools.

The ICBP Nano was born from the desire of more compact heat treatment installations with the smallest footprint, while still maintaining high productivity and very good quenching quality. With a configuration in modules of 3 or 6 stacked up cells, the Nano is able process a load of 100kg every 7 minutes. This vacuum installation has all the characteristics of the ICBP furnaces that have made the reputation of ECM Technologies : clean, flexible & multi-process machines.

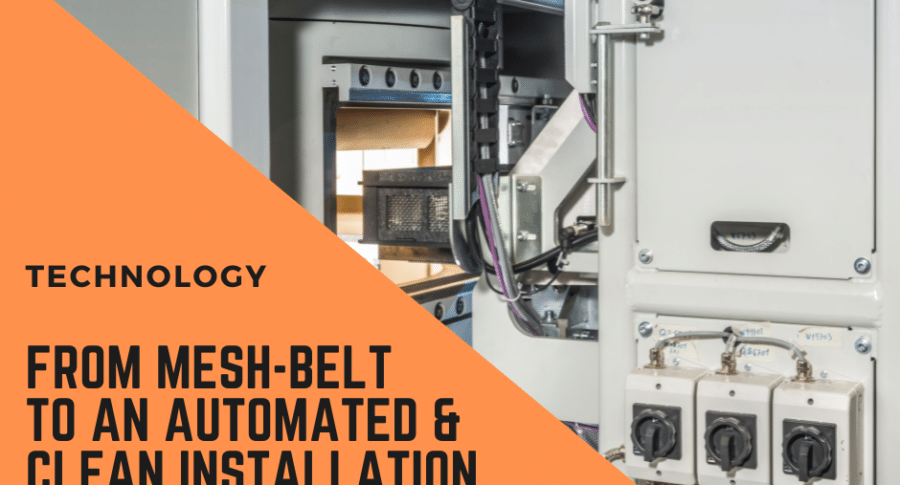

Vacuum technologies as substitutes to mesh-belt furnaces

To develop this installation, ECM Technologies has taken into consideration all of the key characteristics of mesh-belt furnaces (MBF) and has eliminated their disadvantages. Thanks to its compact layout, which is up to four times shorter than a belt furnace, the ICBP Nano can be integrated directly into the manufacturing lines. The installation guarantees a clean and safe working environment thanks to the cold wall technology and the use of vacuum, which does not generate flames and therefore enables no fire hazard.

The integrated gas quenching cell eliminates the need for additional civil engineering costs to create an oil quenching pit, which is usually needed with belt furnaces. It also eliminates a washing step. ECM Technologies’ gas quenching guarantees a very good distortion control and a unrivaled uniformity compared to the random drop of the parts in the oil pit of MBF.

In addition, the vacuum atmosphere of the ICBP Nano guarantees a clean production area without CO2 emissions, whereas MBF mostly perform processes in a carbon atmosphere.

The ICBP Nano is a real alternative to mesh belt furnaces and does not lose any productivity. Indeed, the reduced size of loads allows significant gains in cycle times, which guarantees a high throughput. Moreover, the Nano also allows the heat treatment of parts in bulk.

Expertise in robotics for an automated and autonomous workstation

A division within the ECM Group, ECM Robotics has the capacity to integrate and manage all types of robots for different applications. The Nano has been designed to maximize its compatibility with robotics thanks to its compact design. The furnace, process and robotics ecosystem allows manufacturers to reach their objectives of profitability, flow optimization and quality ; which make ECM Technologies a unique and privileged interlocutor for a complete and robotized heat treatment line.

Indeed, the robotization and automation of processes allow the integration of heat treatment operations in the production lines, without any flow interruption.